Part Size Specifications

Delivering Quality Parts

In Every Size And Scale

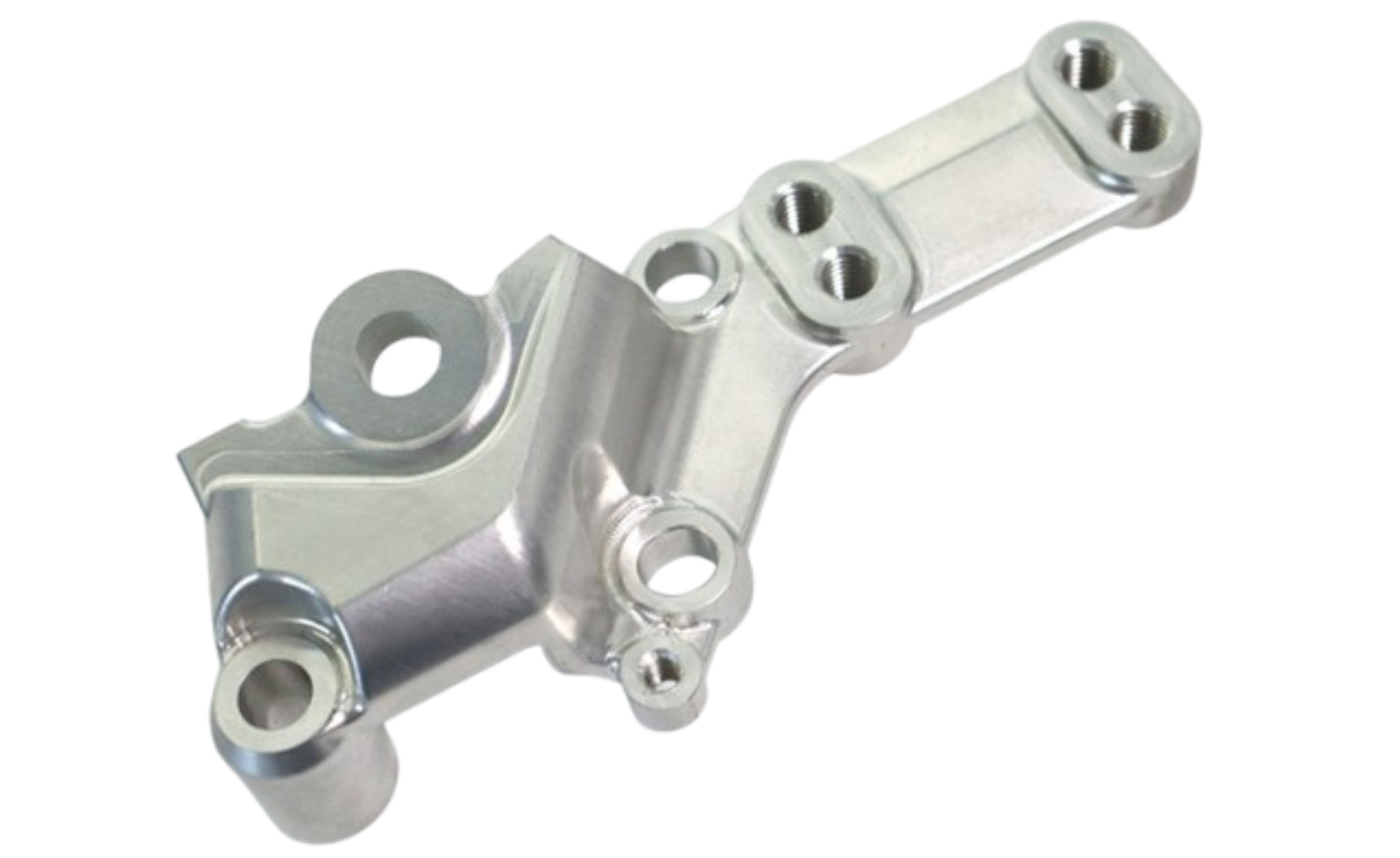

Machined Parts

Precision Machining

CNC Vertical Machining Centers (3, 4, 5-axis) – HAAS VF series & VF-6TR (max part size up to 1524 x 660 x 635 mm)

CNC Lathes – Swiss-type, Y-axis, with live tooling (for diameters up to ~300 mm and lengths up to 1250 mm). Cam-type, with a production capacity of up to 40,000 parts per day.

Drilled Holes

Deep Hole Drilling – Capable of drilling holes up to 1450–1800 mm depth

Comprehensive Grinding – ID/OD, surface, and honing (up to Ø250 mm and lengths ~600 mm).

Forged Parts

Hammer and Standard Forging Machines – Up to 800 tons

Hydraulic and Mechanical Presses – Up to 1000 tons, suitable for parts with cross-sections up to ~500 mm.

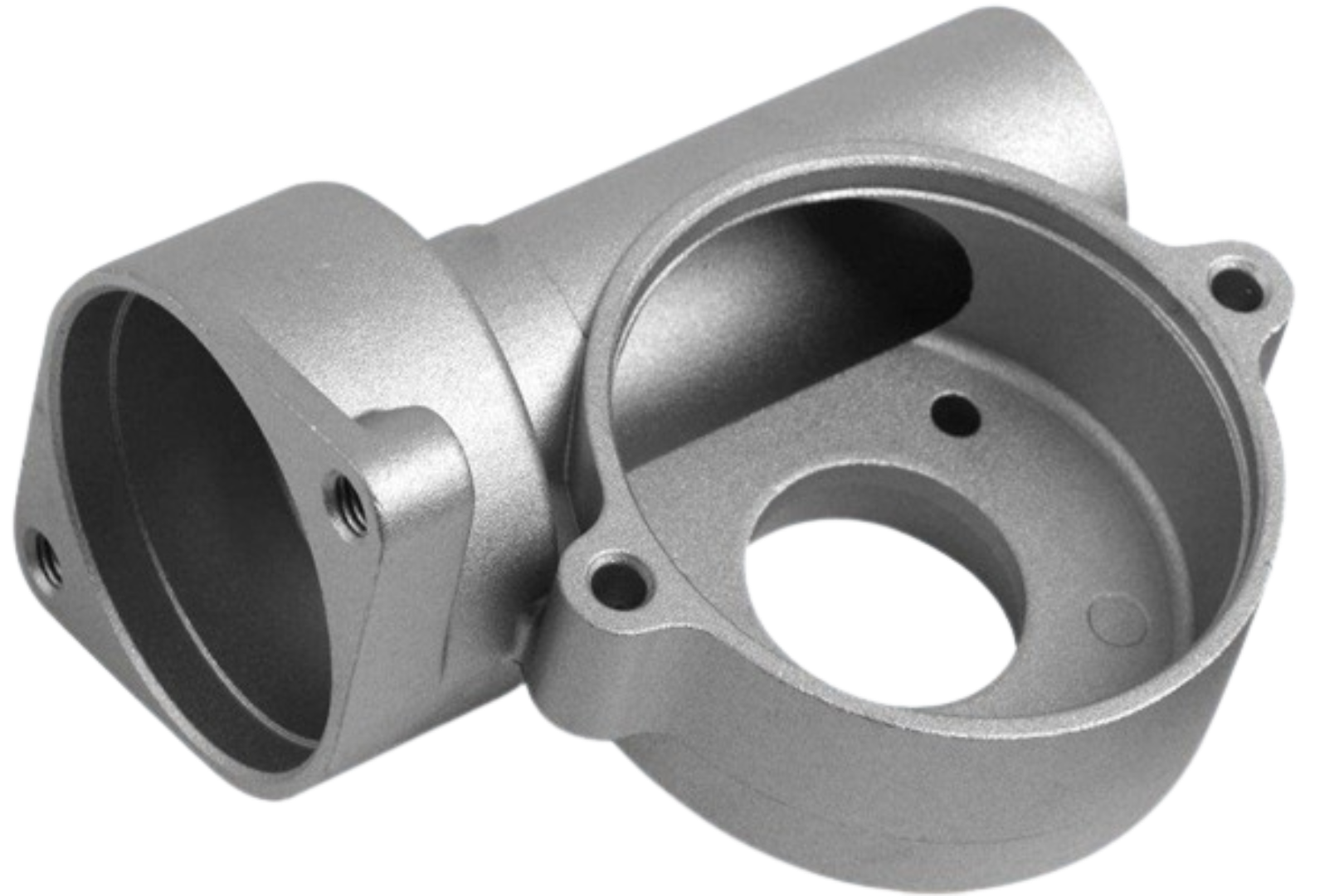

Cast Parts

Investment casting system suitable for parts ranging from a few grams to several kilograms, dimensions typically up to ~300 mm

Powder metallurgy – Capable of producing parts up to 200 mm in size

Aluminum alloy extrusion (series 6xxx and 7xxx) – Profiles up to 20 mm in size

Aluminum die casting (ADC12) – Parts with dimensions up to 200 mm

Aluminum die casting machines with capacities up to 350 tons

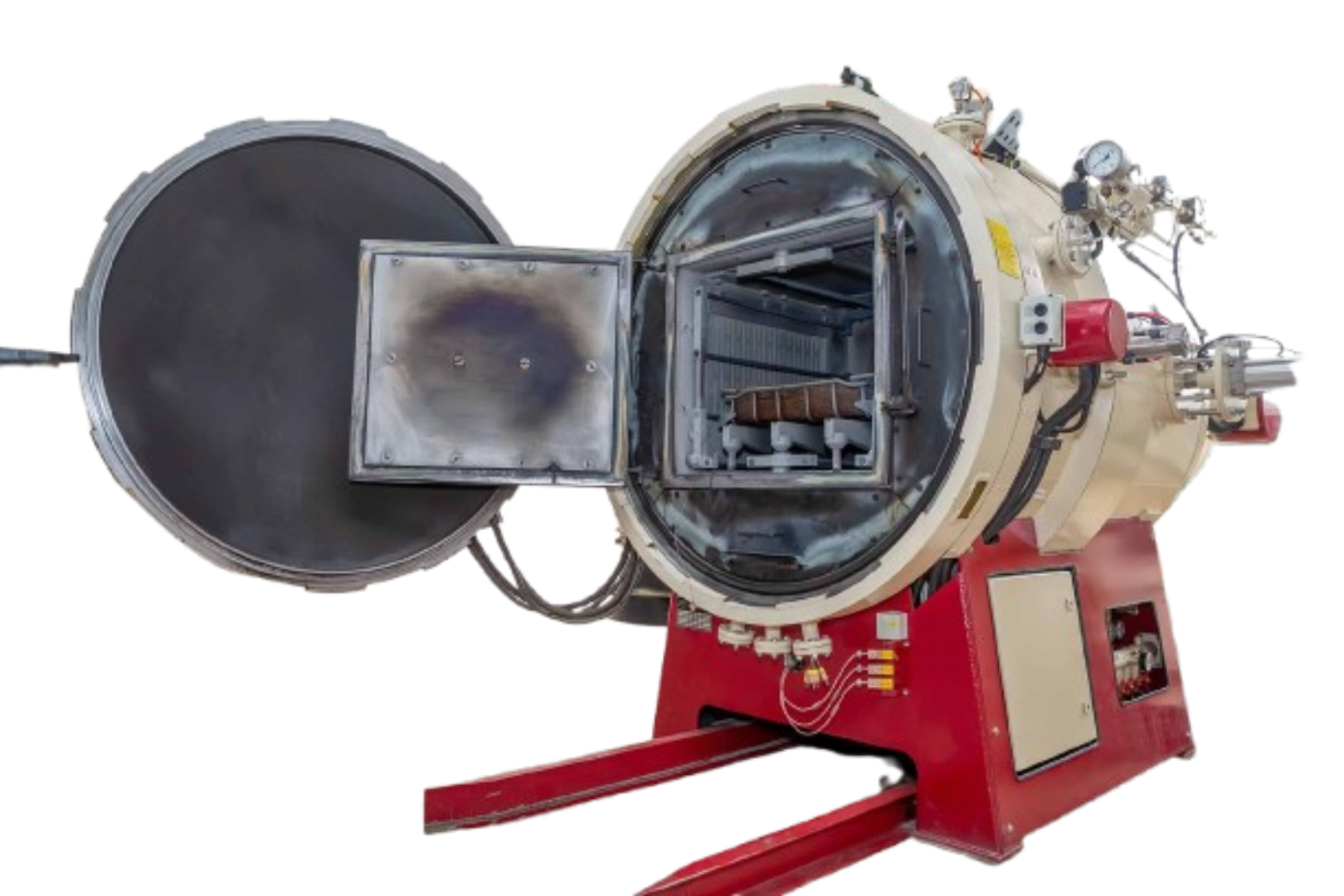

Heat-treated Or Coated Parts

- Heat Treatment

Multi-function Furnace (IPSEN TQ8) – Heat treatment of parts up to ~500 mm in size

Vacuum Heat Treatment – For precision components requiring clean and distortion-free treatment

- Coated parts

Chromium & Phosphate Plating, Anodizing, Oxidation, and Painting

Aluminum Alloy Anodizing System – For parts up to ~500 mm